There was a job for two jackets in a (cheap) light grey wool in twill weave for a father and son. I find it such a great way of bonding. Looking at the jacket, the father is obviously corpulent with quite a gut. The son, however, is physically fit. Here I show the pictures of the son's jacket.

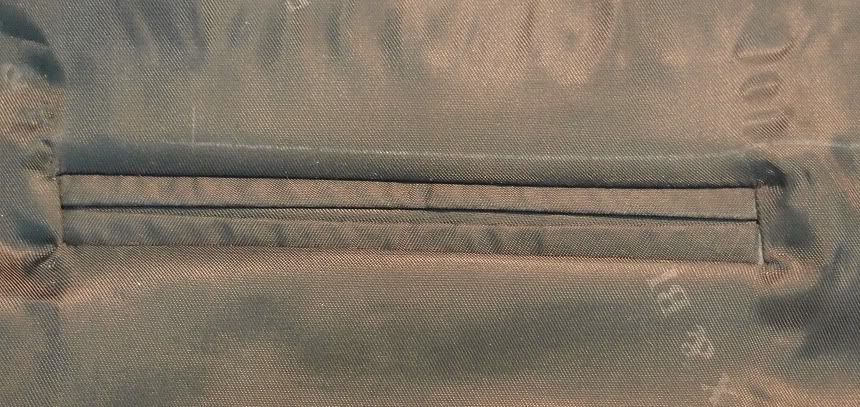

I think the sifu trimmed away a bit too much from the seam allowance that is wrapped by the welt. Hence the small gap between the welts.

I'm not an expert on evaluating sleeves, but that one there looks very fine. I hope the cutter pitched the sleeves right and got the curvature right. It would be a waste if such sleeves did not fit the customer (a very common problem).

The gorge is totally modern.

I see a conservative -- even boring -- cut that is typical of RTW jackets. If the jacket actually fits the customer the visual impact is considerable. However, I have higher expectations of bespoke. I would have expected more quirkiness, more idiosyncracy, more character. And above all more waist suppression.

I think the sifu trimmed away a bit too much from the seam allowance that is wrapped by the welt. Hence the small gap between the welts.

I'm not an expert on evaluating sleeves, but that one there looks very fine. I hope the cutter pitched the sleeves right and got the curvature right. It would be a waste if such sleeves did not fit the customer (a very common problem).

The gorge is totally modern.

I see a conservative -- even boring -- cut that is typical of RTW jackets. If the jacket actually fits the customer the visual impact is considerable. However, I have higher expectations of bespoke. I would have expected more quirkiness, more idiosyncracy, more character. And above all more waist suppression.